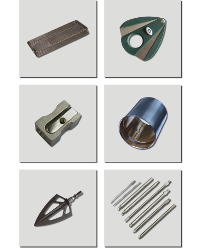

Diverse

Solutions

The Berger Gruppe offers machines for processing workpieces of different shapes and sizes. The machines carry out different processes such as grinding, sharpening, polishing, edge trimming, grooving or profile generating.

The group offers solutions for e. g. razor blades | pencil sharpener blades | welded tubes | hollow profiles | plain bearing bushes | screwdriver blades | screen baskets and more.

Series RTF >

Grinding of brake and clutch discs

Rotary table grinding machine designed for grinding brake and clutch discs with a diameter of up to 1100 mm.

Series RMS >

Rotary table grinding machine for bevel grinding on circular knives with programmable angle adjustment

CNC grinding machine with three or four axes for the grinding of bevels on circular knives by using a cup wheel for high material removal; programmable angle adjustment for the following processing

Series VR >

Rotary table grinding machine for bevel grinding of circular knives with manual angle adjustment

CNC grinding machine with two axes for the grinding of bevels on circular knife blades with a max. diameter of 400 mm (15.7") by using a cup wheel for high material removal, manual angle adjustment

Series RFS/NT >

Peripheral grinding machine for surface and bevel grinding of circular knives

CNC peripheral grinding machine with six axes for the grinding of surfaces, cutting edges and contours on circular knives, saw blades or blanks with oscillating or plunge grinding process

Series RVZ >

Peripheral grinding machine for serrated grinding of circular knives

CNC controlled serrated grinding machine for the machining of circular or cutter knives and for grinding insert seats of bodies of circular knives

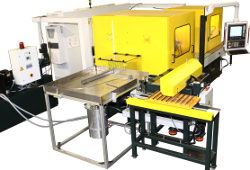

Series BSM3000/E >

Straight finish grinding, scalloped and serrated grinding on one side of steel strips

The steel strip grinding machine is used for one-sided grinding of pencil sharpener blades, abrasor strips, machine blades and similar workpieces.

Series BDG1500 >

Straight finish grinding on steel strips

The strip grinding line of the series BDG1500 consists of five vertical grinding stations and is designed for the production of doctor blades and similar workpieces.

Series BSM3000/P >

Polishing and deburring of steel strips

The polishing station BSM3000/P is designed for polishing and deburring of microground blades such as doctor blades, scalpels, technical blades, pencil sharpener blades and similar workpieces

Breakers >

Breaking units for blades for steel strip grinding machines

The breakers can be integrated into steel strip grinding and polishing lines or be mounted as a separate breaking unit with decoiler.

Spooling systems >

Decoiling systems for steel strip grinding and polishing lines

Augst Nell jr. and Werner Peters offer the following spooling systems which can be integrated into a strip grinding and polishing line.

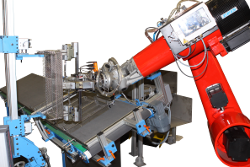

Series RSP/1B/1P/1L >

Grinding and polishing of screen baskets

Robotic grinding and polishing cell with one grinding station, one polishing station and one laser measuring station for the machining of screen baskets and similar workpieces

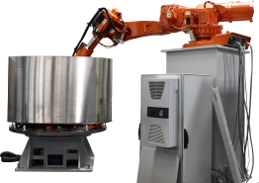

Series RSP/1B >

Grinding of large parts

Grinding station equipped with a special robotic gripper and designed for the machining of large workpieces

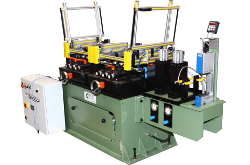

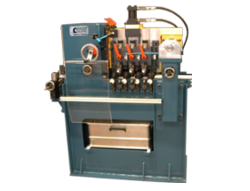

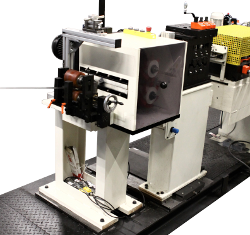

Series UNO >

Strip edge trimming machine with 2 tools

Strip edge trimming machine working with one tool each side. It’s designed for the deburring of the strip edge or for simple contours at the strip edge.

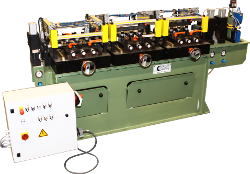

Series DUO >

Strip edge trimming machine with 6 tools

The strip edge trimming machine of the series DUO works with six tools. Often the DUO is integrated into tube production lines to optimize the weld seam.

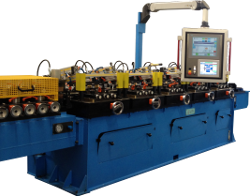

Series TRIO >

Strip edge trimming machine with 9 tools

The TRIO strip edge trimming machine works with up to nine tools achieving even complex contours at the strip edge.

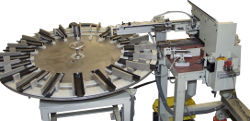

Series QUATTRO >

Strip edge trimming machine with 12 tools

The QUATTRO strip edge trimming machine achieves complex contours on the strip edge with twelve tools.

Series QUINTO >

Strip edge trimming machine with 15 tools

The QUINTO strip edge trimming machine is one of the biggest strip edging machines of the modular series working with 15 tools.

Series BKB/S >

Strip edge trimming machine for heavy duty

The BKB/S is designed for maximum material removal at each tool, which ensures that even complex contours with wide bevels can be machined on strip with heavy cross sections or hard material.

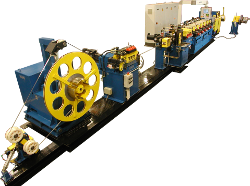

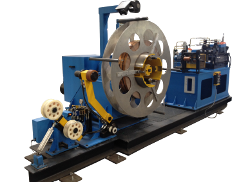

Series BHR/DUO >

Basic strip edge trimming line

The strip edge trimming line of the series BHR/DUO is equipped with a DUO strip edge trimming machine, de- and a re-coiler. It is the basic line of the modular series.

Series BHR/TRIO >

Strip edge trimming line with 9 tools

Strip edge trimming line with a TRIO strip edging machine, a de- and a re-coiler and a strip width measuring system. The line machines strip edges with up to nine tools.

Series BHR/QUATTRO >

Strip edge trimming line with 12 tools

Strip edge trimming line with a strip edging machine of the serie QUATTRO, levelling, measuring and strip tension systems. The line is designed for the machining of complex contours an strip edges.

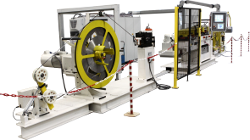

Series BHR/QUINTO >

Strip edge trimming line with 15 tools

Strip edge trimming line with strip edging machine of the series QUINTO, levelling, brushing and calibrating machines as well as measuring and strip tension technique. The line is designed for machining complex contours also on thick and/or smooth strips.

Series BHR/BKB/S >

Strip edge trimming line for heavy-duty applications

The strip edge trimming line of the series BHR/BKB/S is designed for processing under high loads with high material removal.

Series NU >

Grooving machine with one tool

With one tool the grooving machine of the series NU removes a layer of coating from the strip surface. The tool can be adjusted vertically and horizontally.

Series TRINU >

Grooving machine with three tools

The grooving machine of the series TRINU draws up to three grooves into the strip surface with a max. distance of 10 mm (in case of three grooves) or 20 mm (in case of two grooves).

Series NU/S >

Grooving machine for heavy-duty applications

Grooving machine designed for heavy-duty machining with high material removal, removing one layer of coating from the strip surface

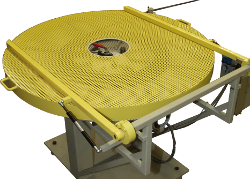

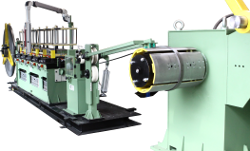

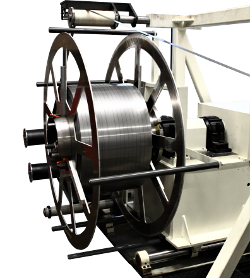

Traverse winding systems >

Traverse winding system and decoiler and the recoiler side

Julius offers traverse winding systems at the recoiler and the decoiler side. It is possible to run in three ways – either from coil to spool, or from multicoil to spool or from spool to spool.

Winding and multicoil systems >

Decoilers and recoilers with and without multicoil system

Decoilers and recoilers can be equipped with a strip tension system, a multicoil system and a traverse winding system. The coilers are integrated into strip processing lines.

Brushing machines >

Brushing machines for strip edge trimming lines

The brushing machines of the series BS remove the dirt particles from the strip surface. They are designed to be integrated into strip edge trimming lines.

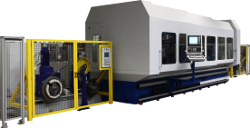

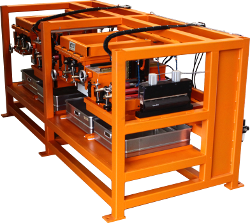

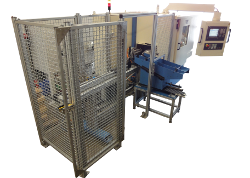

Series LP110 >

Profile generating center

The profile generating center of the series LP110 streamlines the machining processes in the field of polygonal generating and tooth profiling.

Series LP130 >

Profile generating center

The profile generating center of the series LP130 is conceived for medium and heavy-duty machining of polygons, special shapes and radial profiles.