Tube industry

Solutions

The optimization of the strip edge is a basic condition to benefit entirely of the advantages of modern welding methods. Thanks to strip edging, the edges are cleaned meeting requested dimensions.

Advantages: less energy input, higher welding speed, ... read more

Tube welding line by TIN

The Berger Gruppe is part of the Tube Innovation Network.

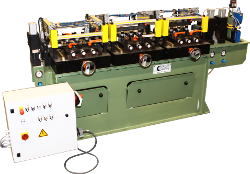

Series UNO >

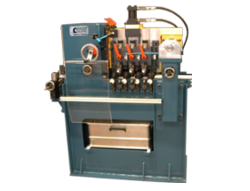

Strip edge trimming machine with 2 tools

Strip edge trimming machine working with one tool each side. It’s designed for the deburring of the strip edge or for simple contours at the strip edge.

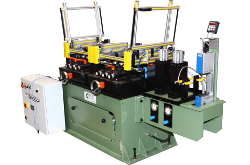

Series DUO >

Strip edge trimming machine with 6 tools

The strip edge trimming machine of the series DUO works with six tools. Often the DUO is integrated into tube production lines to optimize the weld seam.

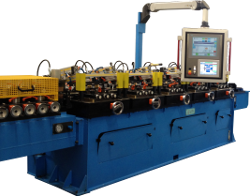

Series TRIO >

Strip edge trimming machine with 9 tools

The TRIO strip edge trimming machine works with up to nine tools achieving even complex contours at the strip edge.

Series QUATTRO >

Strip edge trimming machine with 12 tools

The QUATTRO strip edge trimming machine achieves complex contours on the strip edge with twelve tools.

Series QUINTO >

Strip edge trimming machine with 15 tools

The QUINTO strip edge trimming machine is one of the biggest strip edging machines of the modular series working with 15 tools.

Series NU >

Grooving machine with one tool

With one tool the grooving machine of the series NU removes a layer of coating from the strip surface. The tool can be adjusted vertically and horizontally.

Series TRINU >

Grooving machine with three tools

The grooving machine of the series TRINU draws up to three grooves into the strip surface with a max. distance of 10 mm (in case of three grooves) or 20 mm (in case of two grooves).

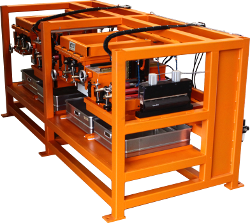

Series NU/S >

Grooving machine for heavy-duty applications

Grooving machine designed for heavy-duty machining with high material removal, removing one layer of coating from the strip surface