Wood processing industry

Solutions

The Berger Gruppe offers solutionsor the machining of workpieces such as secateurs, pruning shears, hedge trimmers, chisels, carving knives or cylinder mowers. CNC-controlled machines of Berger are designed for grinding, serrating, polishing and/or profile generating of the workpieces.

Specially configured robot cells process pliers | wrenches | secateurs | hammer heads | chisels and other workpieces.

The Berger Gruppe will be exhibiting at the upcoming Saw Expo.

Series BG/NT >

Flat bevel grinding machine with horizontal grinding spindle

CNC grinding machine with three to five axes grinding table for the bevel grinding of knives, scissors, hand tools or related parts

Series DG/NT >

Flat bevel grinding machine with vertical grinding spindle

CNC grinding machine with three or four axes and vertical grinding spindle for the surface grinding of knives, scissors, hand tools, and related parts

Series RMS >

Rotary table grinding machine for bevel grinding on circular knives with programmable angle adjustment

CNC grinding machine with three or four axes for the grinding of bevels on circular knives by using a cup wheel for high material removal; programmable angle adjustment for the following processing

Series RFS/NT >

Peripheral grinding machine for surface and bevel grinding of circular knives

CNC peripheral grinding machine with six axes for the grinding of surfaces, cutting edges and contours on circular knives, saw blades or blanks with oscillating or plunge grinding process

Series PH/PB/NT >

Peripheral grinding machine for serrated and scalloped grinding

CNC controlled peripheral grinding machine with additional vertical axis for scalloped grinding and staggered tooth grinding of knives with up to 600 mm grinding length

Series WSL >

Peripheral grinding machine for scalloped and pointed serrated grinding

The grinding station of the series WSL can be integrated into different machines to produce

scalloped or pointed serrated grinding.

Series RVZ >

Peripheral grinding machine for serrated grinding of circular knives

CNC controlled serrated grinding machine for the machining of circular or cutter knives and for grinding insert seats of bodies of circular knives

Series RST >

Rotary index table grinding machine for grinding, serrating and polishing of blades

Rotary index table grinding machine available in various configurations for grinding of steak knives, jig saws, scalpel blades or for the grinding of blades with serration

Series CG >

Contour grinding machine for machining knife blades, tweezers and scissors

CNC grinding machine with two axes for contour grinding of knives, scissors, hand tools, tweezers, scissors and other workpieces

Series BSM3000/E >

Straight finish grinding, scalloped and serrated grinding on one side of steel strips

The steel strip grinding machine is used for one-sided grinding of pencil sharpener blades, abrasor strips, machine blades and similar workpieces.

Series BSM3000/D >

Straight finish grinding, scalloped and serrated grinding on both sides of knives and blades

The double-sided grinding station machines technical blades, doctor blades, surgical blades and similar workpieces on both sides.

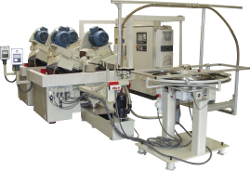

Series SVZ >

Simultaneous serrated edge grinding on multiple 44 strips

The steel strip grinding machine of the series SVZ is designed for edge grinding on steel strips whereas up to 44 strips can be machined at the same time.

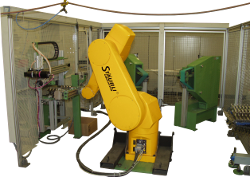

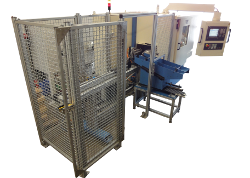

Series RSP/4B/1M >

Grinding of pliers

Robotic cell with four belt grinding station and a magazine system for the machining of pliers and similar workpieces

Series RSP/2B/1K >

Edge and convex grinding of wrenches

Robotic cell with two belt grinding stations and a chain magazine for convex and edge grinding of wrenches and similar pieces

Series RSP/2B/1M (2) >

Grinding and deburring of secateurs

Robotic cell with two belt grinding stations, a flat bevel grinding machine and a rotary table magazine for the machining of secateurs and similar workpieces

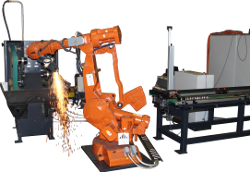

Series RSP/2B (2) >

Grinding of hammer heads

Robotic cell with two belt grinding stations and a belt feeding system for the machining of hammer heads and similar workpieces

Series RSP/4B/1P/1K/1L >

Grinding and polishing of chisels

Robotic cell with four belt grinding stations, a polishing station, a laser measuring system and a chain magazine for the machining of chisels and similar workpieces

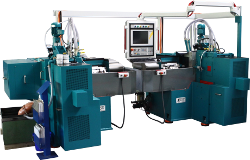

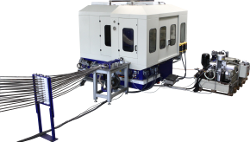

Series BHR/QUATTRO >

Strip edge trimming line with 12 tools

Strip edge trimming line with a strip edging machine of the serie QUATTRO, levelling, measuring and strip tension systems. The line is designed for the machining of complex contours an strip edges.

Series BHR/QUINTO >

Strip edge trimming line with 15 tools

Strip edge trimming line with strip edging machine of the series QUINTO, levelling, brushing and calibrating machines as well as measuring and strip tension technique. The line is designed for machining complex contours also on thick and/or smooth strips.

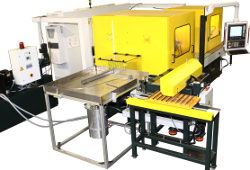

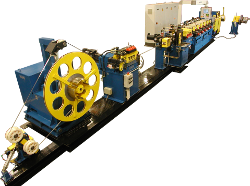

Series LP110 >

Profile generating center

The profile generating center of the series LP110 streamlines the machining processes in the field of polygonal generating and tooth profiling.

Series LP130 >

Profile generating center

The profile generating center of the series LP130 is conceived for medium and heavy-duty machining of polygons, special shapes and radial profiles.