Strip edge trimming machines

Strip processing machines by metal-cutting

The Julius system of strip edge trimming by metal-cutting strips the burr from the strip edge and achieves any contour required.

The modular system makes it possible that the edge trimming units can be combined flexibly and expanded or retrofitted any time from a machine type UNO to a DUO, TRIO, QUATTRO or QUINTO.

The modules are modular in themselves, so that individual assemblies and components can be supplemented and exchanged in each module. Each module has three stations on each side for tool or roll holders. The tools and rolls can be flexibly adjusted and exchanged.

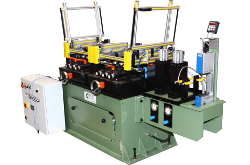

Series UNO >

Strip edge trimming machine with 2 tools

Strip edge trimming machine working with one tool each side. It’s designed for the deburring of the strip edge or for simple contours at the strip edge.

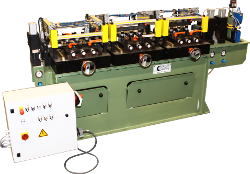

Series DUO >

Strip edge trimming machine with 6 tools

The strip edge trimming machine of the series DUO works with six tools. Often the DUO is integrated into tube production lines to optimize the weld seam.

Series TRIO >

Strip edge trimming machine with 9 tools

The TRIO strip edge trimming machine works with up to nine tools achieving even complex contours at the strip edge.

Series QUATTRO >

Strip edge trimming machine with 12 tools

The QUATTRO strip edge trimming machine achieves complex contours on the strip edge with twelve tools.

Series QUINTO >

Strip edge trimming machine with 15 tools

The QUINTO strip edge trimming machine is one of the biggest strip edging machines of the modular series working with 15 tools.

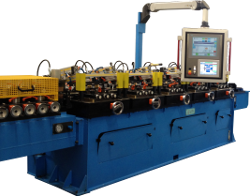

Series BKB/S >

Strip edge trimming machine for heavy duty

The BKB/S is designed for maximum material removal at each tool, which ensures that even complex contours with wide bevels can be machined on strip with heavy cross sections or hard material.