Grinding machines for single workpieces

grinding | glazing | serrating | sharpening

Grinding machines for individual workpieces are used in the cutlery, machine knife, tool and surgical industries, among others. Depending on the application, cup wheels or peripheral grinding wheels are used.

The machines are designed for a wide range of mechanical operations, such as: flat and bevel grinding | radii grinding | surface grinding | scalloped and serrated grinding | sharpening | glazing | contour grinding | hollow grinding

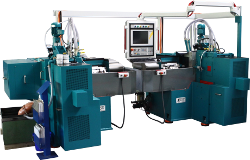

Series BG/NT >

Flat bevel grinding machine with horizontal grinding spindle

CNC grinding machine with three to five axes grinding table for the bevel grinding of knives, scissors, hand tools or related parts

Series DG/NT >

Flat bevel grinding machine with vertical grinding spindle

CNC grinding machine with three or four axes and vertical grinding spindle for the surface grinding of knives, scissors, hand tools, and related parts

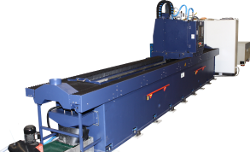

Series FS >

Flat grinding machine for long knives

CNC controlled vertical precision flat grinding machine for flat grinding of long knives with a maximum length of 4,000 mm

Series AS/H >

Flat bevel grinding machine with hydraulical drive for the grinding table

Flat bevel grinding machine with hydraulically driven grinding table for grinding knives, scissors, hand and gardening tools and similar workpieces

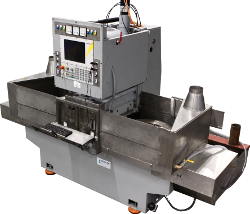

Series HSG >

Flat bevel grinding machine for grinding the head surface of mechanical knives

CNC controlled flat bevel grinding machine designed for lateral grinding of mechanical knives and similar workpieces

Series HDS >

Rotary table grinding machine for double-sided flat grinding of parallel surfaces

CNC grinding machine with three axes for economic double-sided flat grinding of parallel surfaces of e.g. spanner wrenches, pliers, hammers, chisels, swords or flat grinding of conical surfaces such as adjustable spanner wrenches by single grinding (e.g. nippers) or continuous process (e.g. swords)

Series DRG >

Rotary table grinding machine for grinding flat or conical surfaces

High productivity CNC double rotary table grinding machine with two axes for the grinding flat or conical surfaces on a great variety of parts such as table knives, insides of stamped scissors, wood chisels, spatulas or connecting rods

Series DRTS >

Rotary table grinding machine with vertical grinding table for flat grinding

Rotary table grinding machine with vertical grinding table for flat grinding of hammers, screwdrivers, pliers and similar workpieces

Series RTS >

Rotary table grinding machine for surface and angle grinding

Rotary table grinding machine with vertically adjustable spindle for efficient surface and angle grinding in continuous production of pocket knife components, hand tools and similar parts

Series RTF >

Grinding of brake and clutch discs

Rotary table grinding machine designed for grinding brake and clutch discs with a diameter of up to 1100 mm.

Series RMS >

Rotary table grinding machine for bevel grinding on circular knives with programmable angle adjustment

CNC grinding machine with three or four axes for the grinding of bevels on circular knives by using a cup wheel for high material removal; programmable angle adjustment for the following processing

Series VR >

Rotary table grinding machine for bevel grinding of circular knives with manual angle adjustment

CNC grinding machine with two axes for the grinding of bevels on circular knife blades with a max. diameter of 400 mm (15.7") by using a cup wheel for high material removal, manual angle adjustment

Series RFS/NT >

Peripheral grinding machine for surface and bevel grinding of circular knives

CNC peripheral grinding machine with six axes for the grinding of surfaces, cutting edges and contours on circular knives, saw blades or blanks with oscillating or plunge grinding process

Series PH/PB/NT >

Peripheral grinding machine for serrated and scalloped grinding

CNC controlled peripheral grinding machine with additional vertical axis for scalloped grinding and staggered tooth grinding of knives with up to 600 mm grinding length

Series WS >

Peripheral grinding machine for serrated, scalloped and fluted edge grinding of knives and blades

CNC controlled peripheral grinding machine with up to three axes for scalloped, serrated and fluted edge grinding of knives, mechanical knives, industrial blades and similar workpieces

Series WSM >

Peripheral grinding machine for scalloped and pointed serrated grinding

CNC peripheral grinding machine with up to three axes for plunge grinding of serrated edges on knife blades (e.g. bread or steak knives), scissors and similar workpieces

Series KS >

Peripheral grinding machine for fluted edge grinding of knives

CNC controlled peripheral grinding machine with one axis for fluted egde grinding of knives and blades

Series WSL >

Peripheral grinding machine for scalloped and pointed serrated grinding

The grinding station of the series WSL can be integrated into different machines to produce

scalloped or pointed serrated grinding.

Series RVZ >

Peripheral grinding machine for serrated grinding of circular knives

CNC controlled serrated grinding machine for the machining of circular or cutter knives and for grinding insert seats of bodies of circular knives

Series RST >

Rotary index table grinding machine for grinding, serrating and polishing of blades

Rotary index table grinding machine available in various configurations for grinding of steak knives, jig saws, scalpel blades or for the grinding of blades with serration

Series KBR >

Rotary index table grinding machine for machining cutlery edges

The rotary index table grinding machine KBR6 realizes a complete edge machining all-around the workpiece with a machine which consists of two one-sided and two double-sided belt grinding stations.

Series ZS >

Rotary index table grinding machine for tines

The rotary index table grinding machine of the series ZS machines forks with two, three or four tines. By the use of a folded grinding belt the run-out radius is ground cleanly.

Series HG/NT >

Hollow grinding machine for hollow grinding of knives, hand tools and similar pieces

CNC grinding machine with four axes for the double-sided hollow grinding of kitchen and steak knives, hunting and sports knives, pocket knives as well as hand tools like e.g. jigsaw blades

Series PLM/E/H >

Glazing machine for the machining of knife blades

Hydraulic glazing machine for the machining of knife blades and similar workpieces

Series PLM/NT >

Glazing machine for glazing knife blades

CNC glazing machine with three axes for glazing ground knife blades

Series CG >

Contour grinding machine for machining knife blades, tweezers and scissors

CNC grinding machine with two axes for contour grinding of knives, scissors, hand tools, tweezers, scissors and other workpieces

Series SM >

Sharpening machine for knife blades

Sharpening machine for sharpening knife blades and mounted knives

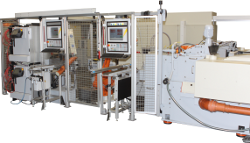

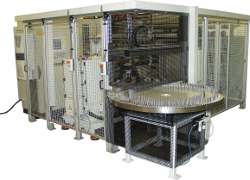

Magazine systems >

Magazine systems for grinding and glazing machines for single workpieces

The design of the loading/unloading magazines is chosen depending on the required capacity, the shape of the workpiece and other parameters.

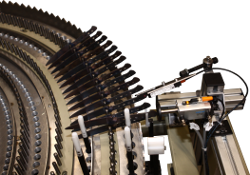

Dressing systems >

Dressing systems for dressing peripheral grinding wheels and cup wheels

Depending from the type of grinding machine and application the Berger Gruppe offers different dressing systems for peripheral grinding wheels and cup wheels.

Fixtures >

Clamping tools for grinding and glazing machines

Mechanical, pneumatic and electromagnetic fixtures designed for grinding and glazing machines for single workpieces

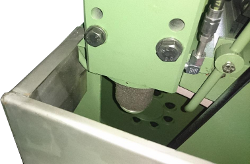

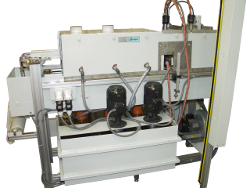

Coolant systems >

Cooling systems for grinding machines

In combination with grinding machines the Berger Gruppe offers a variety of different designs for cleaning systems for grinding emulsion.

Cleaning systems >

Cleaning and drying of workpieces

For the cleaning/drying of workpieces a cleaning and drying station can be integrated into the machinery.

Abrasives >

Abrasives: Peripheral grinding wheels and cup wheels

In addition to grinding machines, BERGER is manufacturing and selling a variety of peripheral and cup wheels.

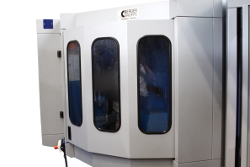

Full enclosure >

Full encasement for grinding and glazing machines

The Berger Gruppe offers full encasement for different series of grinding and glazing machines.

Exhausting device for grinding machines >

Exhausting device for cooling lubricant mists

The Berger Gruppe offers a suction device to aspire cooling lubricant mists.