Accessories

Strip processing machines by metal-cutting

Accessories for strip processing machines: swarf removal system | tool holders | TRISTEP

Components for strip processing lines: brushing machines | levelling machines | measuring stations | strip tension regulating systems | traverse winding systems | winding and multicoil systems

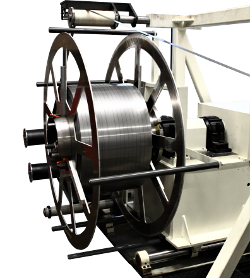

Traverse winding systems >

Traverse winding system and decoiler and the recoiler side

Julius offers traverse winding systems at the recoiler and the decoiler side. It is possible to run in three ways – either from coil to spool, or from multicoil to spool or from spool to spool.

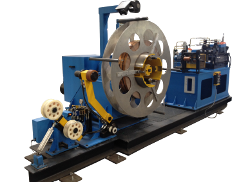

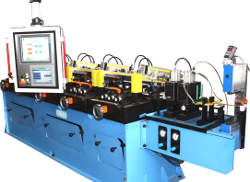

Winding and multicoil systems >

Decoilers and recoilers with and without multicoil system

Decoilers and recoilers can be equipped with a strip tension system, a multicoil system and a traverse winding system. The coilers are integrated into strip processing lines.

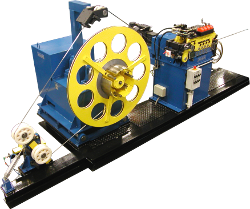

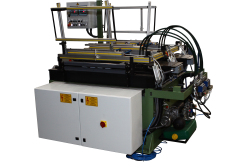

Strip tension regulating systems >

Strip tension technique for strip edge trimming lines

Some operational treatment of the strip – e. g. machining of complex contours or beveling – exerts excessive strip tension for save recoiling of strip with weak cross sections. If so, a S-bridel and a dancer will regulate the strip tension to a tolerable level.

Levelling machines >

Flat levelling, vertical levelling and calibrating of strips

Machines for flat and vertical levelling and calibrating of strips. The machines are integrated into strip processing lines.

Brushing machines >

Brushing machines for strip edge trimming lines

The brushing machines of the series BS remove the dirt particles from the strip surface. They are designed to be integrated into strip edge trimming lines.

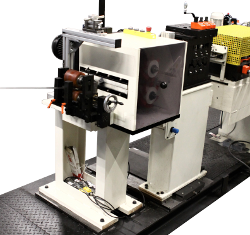

TRISTEP >

Motor adjustment of tools in strip edging machines

The TRISTEP system features a motorized adjustment of the tools on the non-operator side and – if desired – also of the tools on the operator side. It can be integrated into in JULIUS strip edging machines

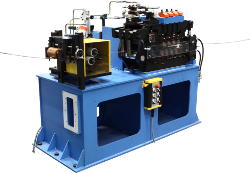

Swarf removal systems >

Swarf removal for strip edge trimming lines

Different modules can be integrated into strip processing lines to remove the swarfs such as swarf hoppers, swarf shredders, conveyor belts for swarf removal or swarf deflecting plates.

Tool holders >

Tool and roll holders for strip edge trimming machines

The Berger Gruppe offers a big range of tool and roll holders for different applications. Due to the modular system it is possible to combine tool and roll holders flexibly and to exchange them at any time.

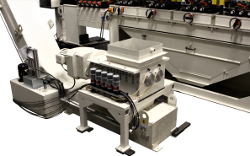

Measuring stations >

Measuring technique and CNC technology

The Berger Gruppe offers strip edge and strip surface treatment by metal-cutting in a closed loop. Strip width, contour and residual wall thickness of the groove are measured and automatically restored to preset tolerance ranges.