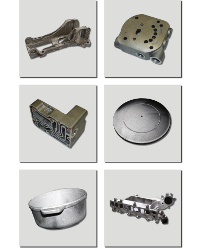

Cast or forged parts

Solutions

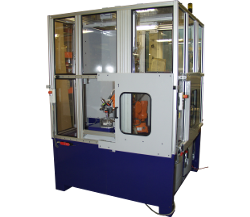

The Berger Gruppe offers different robotic cells for the machining of pressure die castings and cast-iron parts. Depending on the characteristics of the workpiece either the workpiece or the tools can be robotic-controlled.

The company will present the latest developments in the field of fettling and deburring of cast parts at several trade shows such as Deburring Expo, GIFA and Euroguss.

Catalogue for foundry industry

Series RSP/2B/1F >

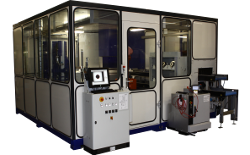

Grinding and deburring of cast iron parts

Robotic grinding and deburring cell with two belt grinding stations and one deburring station for the machining of cast iron parts such as cast iron pots

Series RSP/5S/1R/1L >

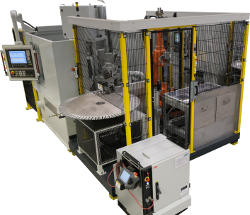

All-round grinding and deburring of workpieces

Robotic cell with five processing stations installed on a CNC rotary table for grinding and deburring workpieces

Series RSP/5F >

Deburring of pressure casting / steel casting

Robotic deburring cell with three milling and brushing spindles for the machining of pressure casting and steel casting parts

Series RSP/5F/3R >

Deburring and milling of pressure die castings

The robotic cell RSP/5F/3R machines casting parts with up to five tools.

Series RSP/1B/1R >

Short descriptionDescription

Series RSP/1F/1R/1M/1L >

Deburring of large-volume workpieces

The fully automated robot cell is designed for deburring large-volume workpieces.

The feeding is carried out by the customer via a loading and unloading position. From then on, the workpiece is machined fully automatically