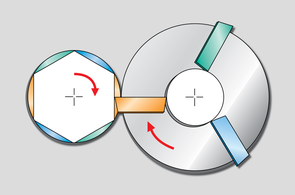

Example of use: Horizontal generating system

Series LP110 and LP130

Typical workpieces for horizontal generating system

The workpieces shown here are examples of machining with the horizontal generating system.

Machining time for different machining operations

- 4 front lugs: 10.0 s

- Hexagon AF 15 mm: 9.0 s

- 4 lugs with 5° relief cut: 10.0 s

- 2 clutch lugs: 11.7 s

- 9 clutch lugs: 8.0 s

- Square AF 1/2“: 6.0 s

- 2 drive lugs AF 13 mm: 18.0 s

- Wood drill head profile Ø 35 mm: 20.0 s

- Universal front side with cross holes Ø 6,5 mm: 25.0 s

- Front face geometry with center slot: 11.0 s

- 2 front lugs: 9.0 s

- Bi-flat AF 7 with radius facets and radius runout: 18.0 s

- 3 drive lugs: 8.0 s

- Complete frontend geometry Ø 12 mm: 9.0 s

- Front slot 10 mm × 20 mm: 6.0 s

- Triangle: 5.0 s

- Square AF 12 mm: 20.0 s

- Square tapered AF 1/2“: 8.0 s

- Square tanks AF 16 mm: 12.0 s

- Square AF 20 mm: 10.0 s

- Hexagon AF 30 mm stainless steel: 9.0 s

- Slotted screwdriver blade – bi-flat: 5.0 s

- Ball-end hexagon AF 8 mm: 6.0 s