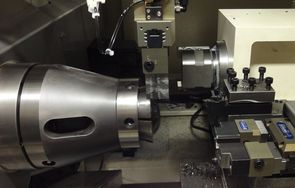

Exemple of use: Extension for socket wrenches

Series LP130

Extension for socket wrenches

For a perfect production of extensions, the processing on LP130 is divided into different operations carried out at the same time.

The production of extensions is executed in three operations:

- turning

- machining of the square

- drilling

In the first processing station the contour of the piece is turned and the square is generated.

Afterwards, the workpiece is transported to the second processing station – the drilling station. For reasons of rigidity the drilling station is fixed on the machine base.

With CNC control the drilling station drills a cross-hole with a diameter of 2.5–6.6 mm into the square.

The next square is machined simultaneously to the drilling operation.