Exemple of use: Universal generating system

Series LP110 and LP130

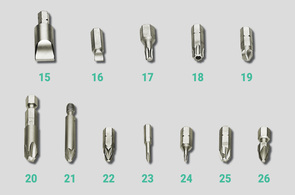

Typical workpieces for Universal Generating Center

The profile generating center equipped with a universal generating system is designed for screwdriver blades and bits. Blade length up to approx. 400 mm and bits up to approx. 75 mm are automatically fed through the hollow shaft of the workpiece spindle nose. This reduces magazine changing times a lot.

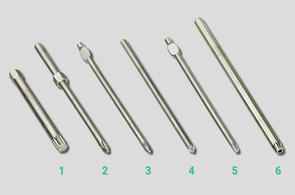

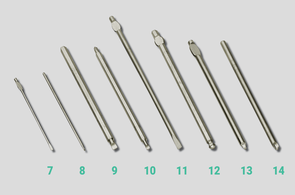

The components available for the screwdriver industry include Phillips, Pozidriv, Torx, Tamper Torx, hexagonal ball-ended, flat blade (dihedral), Torq-Set, Tri-Wing, double-flat, square, hexagonal etc.

Machining time for different machining operations

- Triple square tip: 7.0 s

- Screwdriver blade Phillips size 2: 2.0 s

- Screwdriver blade Phillips size 1: 2.0 s

- Screwdriver blade Pozidriv size 2: 3.7 s

- Screwdriver blade Torx size T 25: 2.0 s

- Tamper Torx blade size T 40: 6.0 s

- Flat screwdriver blade: 6.0 s

- Flat screwdriver blade with turning: 7.0 s

- Flat screwdriver blade with turning: 7.0 s

- Phillips size 1 and 2 with turning: 7.0/6.5 s

- Flat screwdriver blade: 7.0 s

- Ball end on hexagon shank: 4.5 s

- Square recess screwdriver blade: 4.5

- Screwdriver blade, Tri Wing: 8.0 s

- Flat Bit blade: 10.0 s

- Flat Bit blade with turning: 6.5 s

- Torx-Bit size T 30 with turning: 6.5 s

- Tamper Torx Bit size T 40: 6.5 s

- Torq Set Bit: 10.0 s

- Phillips Bit size 3: 2.5 s

- Pozidriv Bit size 1: 3.5 s

- Pozidrive Bit size 3: 4.0 s

- Phillips-Bit Gr. 0 with turning: 6.0 s

- Torx-Bit size T 6 with turning: 8.0 s

- Pozidrive Bit size 2: 3.7 s

- Special hexagon Bit Phillips size 2: 3.0 s