Aluminium-Gussteile wie z. B. Zylinderköpfe können mit Hilfe von Robotersystemen entgratet werden ... (mehr lesen)

Durch Kantenbearbeitung wird das Band für die Herstellung von Gleitlagerbuchsen und Halblagerschalen optimiert ... (mehr lesen)

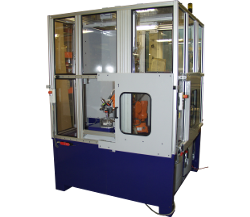

Eine CNC-gesteuerte Schleifmaschine ist für das Schleifen von Brems- und Kupplungsscheiben konzipiert ... (mehr lesen)

Baureihe RTF >

Rundtisch-Schleifmaschine zum Schleifen von Brems- und Kupplungsscheiben

Rundtisch-Schleifmaschine zum Schleifen von Brems- und Kupplungsscheiben mit einem Durchmesser von bis zu 1100 mm

Baureihe RSP/5F >

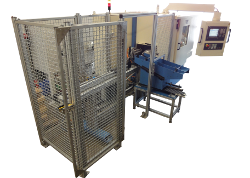

Entgraten von Druckguss / Stahlguss

Roboter-Entgratzelle mit drei Fräs- und Bürstspindeln zur Bearbeitung von Druckguss- und Stahlgussteilen

Baureihe RSP/5F/3R >

Entgraten und Fräsen von Druckgussteilen

Die Roboterstation RSP/5F/3R bearbeitet mit bis zu fünf Werkzeugen Druckgussteile.

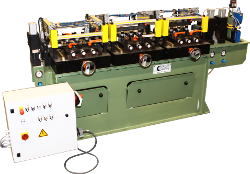

Baureihe UNO >

Bandkantenbearbeitungsmaschine mit 2 Werkzeugen

Bandkantenbearbeitungsmaschine mit einem Werkzeug pro Seite. Die UNO ist zum Entgraten der Bandkante und zum Erzielen von einfachen Konturen an der Bandkante konzipiert.

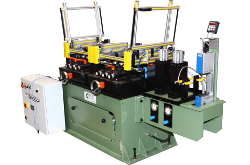

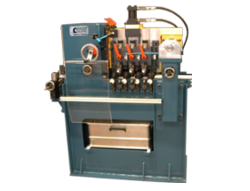

Baureihe DUO >

Bandkantenbearbeitungsmaschine mit 6 Werkzeugen

Die Bandkantenbearbeitungsmaschine der Baureihe DUO bearbeitet die Bandkante mit sechs Werkzeugen. Die DUO wird oft zur Schweißnahtvorbereitung in Rohrschweißstraßen integriert.

Baureihe TRIO >

Bandkantenbearbeitungsmaschine mit 9 Werkzeugen

Die Bandkantenbearbeitungsmaschine der Baureihe TRIO arbeitet mit bis zu neun Werkzeugen und erzielt komplexe Konturen an der der Bandkante.

Baureihe QUATTRO >

Bandkantenbearbeitungsmaschine mit 12 Werkzeugen

Die Bandkantenbearbeitungsmaschine der Baureihe QUATTRO erzielt mit zwölf Werkzeugen komplexe Konturen an der Bandkante.

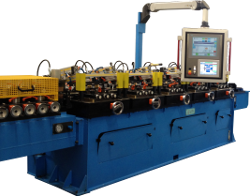

Baureihe QUINTO >

Bandkantenbearbeitungsmaschine mit 15 Werkzeugen

Die Bandkantenbearbeitungsmaschine der Baureihe QUINTO ist eine der größten Bandkantenbearbeitungsmaschinen der modularen Baureihe und bearbeitet die Bandkanten mit 15 Werkzeugen.

Baureihe BKB/S >

Bandkantenbearbeitungsmaschine für starke Beanspruchung

Die BKB/S ist so konzipiert, dass sie vom ersten Werkzeug an viel Material abtragen und so auch an dicke und harte Bänder eine komplexe Kontur mit breiten Fasen anarbeiten kann.

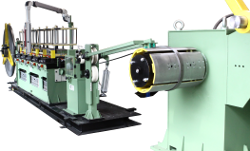

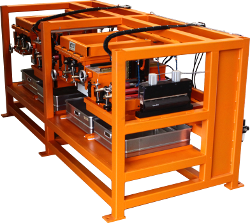

Baureihe BHR/DUO >

Basis Bandkantenbearbeitungsanlage

Die Bandkantenbearbeitungsanlage der Baureihe BHR/DUO ist mit einer DUO Bandkantenbearbeitungsmaschine, einem Ab- und einem Aufwickler ausgestattet. Es ist die Basisanlage in der modularen Baureihe.

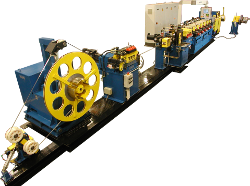

Baureihe BHR/TRIO >

Bandkantenbearbeitungsanlage mit 9 Werkzeugen

Bandkantenbearbeitungsanlage mit einer TRIO-Bandkantenbearbeitungsmschine, einem Ab- und einem Aufwickler sowie einem Bandbreitenmesssystem. Die Anlage bearbeitet die Bandkanten mit bis zu neun Werkzeugen.

Baureihe BHR/QUATTRO >

Bandkantenbearbeitungsanlage mit 12 Werkzeugen

Anlage mit Bandkantenbearbeitungsmaschine der Baureihe QUATTRO sowie Richtmaschine und Mess- und Bandzugtechnik. Die Anlage ist für die Anarbeitung von komplexen Konturen an die Bandkanten konzipiert.

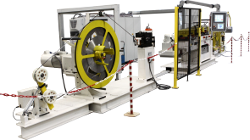

Baureihe BHR/QUINTO >

Bandkantenbearbeitungsanlage mit 15 Werkzeugen

Anlage mit Bandkantenbearbeitungsmaschine der Baureihe QUINTO, Richt-, Bürst- und Kalibriermaschinen sowie Mess- und Bandzugtechnik. Die Anlage ist für die Anarbeitung komplexer Konturen auch an dicke und/oder weiche Bänder konzipiert.

Baureihe BHR/BKB/S >

Bandkantenbearbeitungsanlage für starke Beanspruchung

Die Bandkantenbearbeitunsanlage der Baureihe BHR/BKB/S ist für die Bearbeitung unter hoher Belastung mit einem hohen Materialabtrag konzipiert.

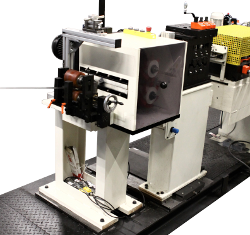

Baureihe NU >

Nutenziehmaschine mit einem Werkzeug

Die Nutenziehmaschine der Baureihe NU entfernt mit einem Werkzeug eine Bahn der Beschichtung von der Bandoberfläche. Das Werkzeug kann horizontal und vertikal eingestellt werden.

Baureihe TRINU >

Nutenziehmaschine mit drei Werkzeugen

Die Nutenziehmaschine der Baureihe TRINU zieht bis zu drei Nuten in die Bandoberfläche mit einem maximalen Abstand von 10 mm (bei drei Nuten) oder 20 mm (bei zwei Nuten).

Baureihe NU/S >

Nutenziehmaschine für Bearbeitungen unter hoher Belastung

Die für die Bearbeitung unter hoher Belastung mit hohem Materialabtrag konzipierte Nutenziehmaschine entfernt eine Spur der Beschichtung von der Bandoberfläche.

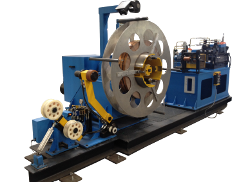

Spulsysteme >

Spulsystem an Ab- und Aufwickler

JULIUS bietet Spulsysteme für Auf- und Abwickler an. Es ist möglich, auf drei Arten zu arbeiten – von Coil zu Spulcoil, von Multicoil zu Spulcoil oder von Spulcoil zu Spulcoil.

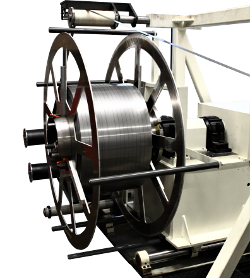

Wickel- und Multicoilsysteme >

Abwickler und Aufwickler mit und ohne Multicoilsystem

Abwickler und Aufwickler können mit Bandzugtechnik, Multicoilsystem und Spulsystem ausgestattet werden. Die Haspeln werden in Bandbearbeitungsanlagen integriert.

Bürstmaschinen >

Bürstmaschinen für Bandkantenbearbeitungsanlagen

Die Bürstmaschinen der Baureihe BS entfernen Schmutzpartikel von der Bandoberfläche. Sie sind für den Einsatz in Bandkantenbearbeitungsanlagen konzipiert.

Baureihe LP110 >

Wälzschlagzentrum

Das Profilier- und Wälzschlagzentrum der Baureihe LP110 rationalisiert die spanende Fertigung im Bereich des Mehrkantschlagens und Verzahnens.

Baureihe LP130 >

Wälzschlagzentrum

Das Profilier- und Wälzschlagzentrum der Baureihe LP130 ist für die mittlere bis schwere Zerspanung von Mehrkanten, Sonder- und Radialprofilen konzipiert.