Surgical industry

Solutions

The Berger Gruppe uses CNC and robot technology for the mechanical processing of surgical workpieces. A big range of machines and robotic cells are available for the machining of surgical workpieces.

Together with the company Otto Röhrig, the Berger Gruppe organizes the "Conference Production Technology for Surgical Industry".

The Berger Gruppe is part of the permanent exhibition ACIG MEDICAL.

Series BG/NT >

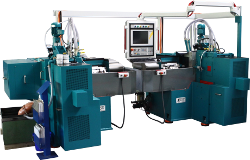

Flat bevel grinding machine with horizontal grinding spindle

CNC grinding machine with three to five axes grinding table for the bevel grinding of knives, scissors, hand tools or related parts

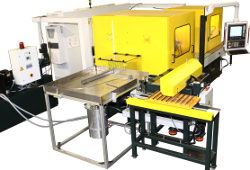

Series DG/NT >

Flat bevel grinding machine with vertical grinding spindle

CNC grinding machine with three or four axes and vertical grinding spindle for the surface grinding of knives, scissors, hand tools, and related parts

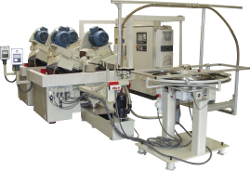

Series RST >

Rotary index table grinding machine for grinding, serrating and polishing of blades

Rotary index table grinding machine available in various configurations for grinding of steak knives, jig saws, scalpel blades or for the grinding of blades with serration

Series CG >

Contour grinding machine for machining knife blades, tweezers and scissors

CNC grinding machine with two axes for contour grinding of knives, scissors, hand tools, tweezers, scissors and other workpieces

Series BSM3000/E >

Straight finish grinding, scalloped and serrated grinding on one side of steel strips

The steel strip grinding machine is used for one-sided grinding of pencil sharpener blades, abrasor strips, machine blades and similar workpieces.

Series BSM3000/D >

Straight finish grinding, scalloped and serrated grinding on both sides of knives and blades

The double-sided grinding station machines technical blades, doctor blades, surgical blades and similar workpieces on both sides.

Series BSM3000/P >

Polishing and deburring of steel strips

The polishing station BSM3000/P is designed for polishing and deburring of microground blades such as doctor blades, scalpels, technical blades, pencil sharpener blades and similar workpieces

Series PS >

CNC controlled polishing of knife handles, bone plates and similar workpieces

The CNC controlled double shaft polishing machine of the series PS is equipped with a control system which enables a programming and storing of all process parameters.

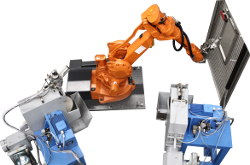

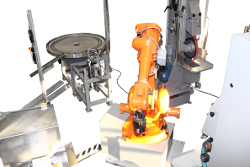

Series RSP/4B/1M/1K (2) >

Facet grinding of scissors

Robotic grinding cell with four belt grinding stations for facet grinding of coated scissors

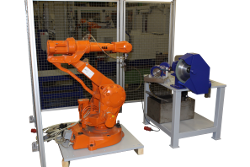

Series RSP/2P >

Polishing of hip joints

Robotic polishing cell with two polishing stations for the machining of artificial hip joints and similar workpieces

Series RSP/4B/1P >

All-around machining of surgical tweezers

Robotic station with four belt grinding stations and a polishing station for grinding and polishing of surgical tweezers

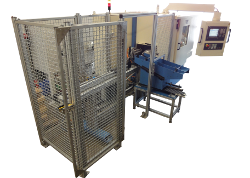

Series RSP/1S >

Sharpening of disposable micro scissors

Robotic sharpening cell with double-sided sharpening station for the machining of disposable blades and micro scissors

Series LP110 >

Profile generating center

The profile generating center of the series LP110 streamlines the machining processes in the field of polygonal generating and tooth profiling.

Series LP130 >

Profile generating center

The profile generating center of the series LP130 is conceived for medium and heavy-duty machining of polygons, special shapes and radial profiles.