Rotary table grinding machines

Grinding machines for single workpieces

The rotary table grinding machines are designed for flat grinding of flat and conical surfaces and for bevel grinding of circular knives.

Series HDS >

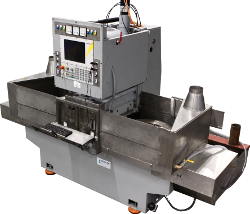

Rotary table grinding machine for double-sided flat grinding of parallel surfaces

CNC grinding machine with three axes for economic double-sided flat grinding of parallel surfaces of e.g. spanner wrenches, pliers, hammers, chisels, swords or flat grinding of conical surfaces such as adjustable spanner wrenches by single grinding (e.g. nippers) or continuous process (e.g. swords)

Series DRG >

Rotary table grinding machine for grinding flat or conical surfaces

High productivity CNC double rotary table grinding machine with two axes for the grinding flat or conical surfaces on a great variety of parts such as table knives, insides of stamped scissors, wood chisels, spatulas or connecting rods

Series DRTS >

Rotary table grinding machine with vertical grinding table for flat grinding

Rotary table grinding machine with vertical grinding table for flat grinding of hammers, screwdrivers, pliers and similar workpieces

Series RTS >

Rotary table grinding machine for surface and angle grinding

Rotary table grinding machine with vertically adjustable spindle for efficient surface and angle grinding in continuous production of pocket knife components, hand tools and similar parts

Series RTF >

Grinding of brake and clutch discs

Rotary table grinding machine designed for grinding brake and clutch discs with a diameter of up to 1100 mm.

Series RMS >

Rotary table grinding machine for bevel grinding on circular knives with programmable angle adjustment

CNC grinding machine with three or four axes for the grinding of bevels on circular knives by using a cup wheel for high material removal; programmable angle adjustment for the following processing

Series VR >

Rotary table grinding machine for bevel grinding of circular knives with manual angle adjustment

CNC grinding machine with two axes for the grinding of bevels on circular knife blades with a max. diameter of 400 mm (15.7") by using a cup wheel for high material removal, manual angle adjustment