Polishing machines

rough polishing | final polishing

The Berger Gruppe offers a big range of polishing machines for single workpieces. Depending on the application, the machines are equipped with one or two shafts. The mechanical surface finishing is carried out with elastic tools such as abrasive belts, grinding and polishing tools, sisal discs or cloth discs.

The machines are used for rough and final polishing of cutlery parts and knife blades or for chamfer polishing on circular knives.

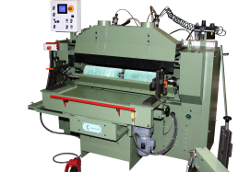

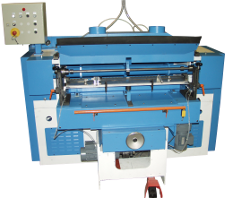

Series DWP >

Rough and final polishing of cutlery items

For rough and final polishing of spoons and forks different models of the series DWP are assembled to one production line.

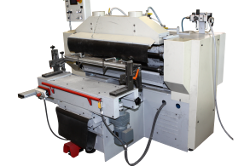

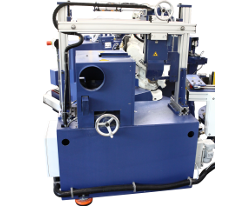

Series DWP/2S >

Polishing of forks and cutlery knives

The double shaft polishing machine type DWP/2S polishes both sides of forks, cutlery knives and similarly shaped workpieces.

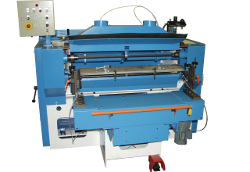

Series DWP/2M >

Polishing knife handles

The double shaft polishing machine type DWP/2M is designed for polishing of knife handles at monobloc knives, mounted knives and hollow handles.

Series DWP/2K >

Polishing the outer edge of cutlery parts

The polishing machine type DWP/2K polishes the edges of cutlery bowls and handles in two steps.

Series DS >

Polishing of the handle neck

The double shaft polishing machine of the series DS is used for rough and final polishing of the narrow edge area of the handle neck (transition between handle and bowl) of spoons, forks and similar workpieces.

Series PS >

CNC controlled polishing of knife handles, bone plates and similar workpieces

The CNC controlled double shaft polishing machine of the series PS is equipped with a control system which enables a programming and storing of all process parameters.

Series PC >

CNC controlled polishing of knife blades

The CNC controlled double shaft polishing machine of the series PC is designed for rough and final polishing of knife blades up to a length of 650 mm.

Series EB >

Polishing of the outer edge of cutlery part ends

The single shaft polishing machine of the series EB is an end facing machine. Depending on its configuration, it can be used for rough or final polishing of spoons, forks or similar items.

Series EWP >

Polishing of deep cutlery bowls

The automatic single shaft polishing machine of the series EWP machines the inner and outer side of cutlery bowls.

Series FPV >

Polishing the cutting edges of circular knives

The FPV series polishing machine is designed for sharpening and polishing the cutting edges of circular knives.

Series ET and UT >

Clamping and exchanging tables

Automatic and manual clamping and exchanging tables are available for all polishing machines and different kind of workpieces.

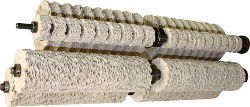

Polishing agent >

Polishing agent and buffing material for Hauschild polishing machines

In co-operation with various manufacturers of polishing and buffing material we can offer the right choice configuration for your application.