Grooving machines

Strip processing machines by metal-cutting

For some work processes it is necessary to treat the strip surface in order to be able to feed the strip to further production processes.

The grooving machines draw one or more grooves into the strip surface. Groove depth and width as well as the number of grooves are variable depending on the series.

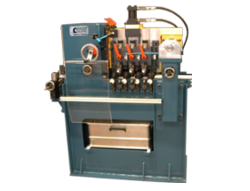

Series NU >

Grooving machine with one tool

With one tool the grooving machine of the series NU removes a layer of coating from the strip surface. The tool can be adjusted vertically and horizontally.

Series TRINU >

Grooving machine with three tools

The grooving machine of the series TRINU draws up to three grooves into the strip surface with a max. distance of 10 mm (in case of three grooves) or 20 mm (in case of two grooves).

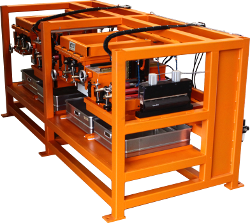

Series NU/S >

Grooving machine for heavy-duty applications

Grooving machine designed for heavy-duty machining with high material removal, removing one layer of coating from the strip surface