Knives

Solutions

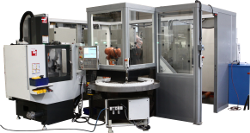

The Berger Gruppe offers machines and robotic cells for processing knives. In conjunction with the association of cutlery industry (IVSH) in Germany, the company organizes on a regular base a cutlery symposium.

The Berger Gruppe will exhibit at the upcoming GrindTec 2023 in Leibzig (Germany).

Download catalogue cutlery industry

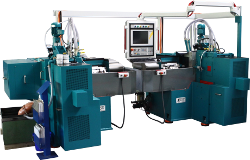

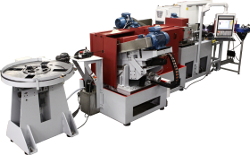

Series BG/NT >

Flat bevel grinding machine with horizontal grinding spindle

CNC grinding machine with three to five axes grinding table for the bevel grinding of knives, scissors, hand tools or related parts

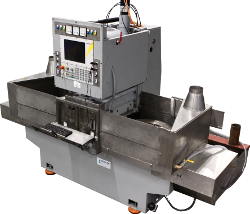

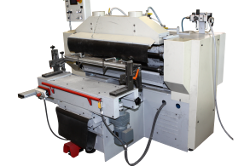

Series DG/NT >

Flat bevel grinding machine with vertical grinding spindle

CNC grinding machine with three or four axes and vertical grinding spindle for the surface grinding of knives, scissors, hand tools, and related parts

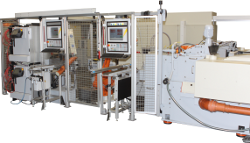

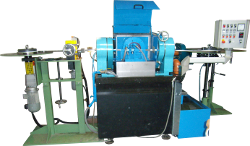

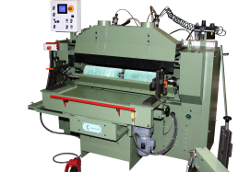

Series AS/H >

Flat bevel grinding machine with hydraulical drive for the grinding table

Flat bevel grinding machine with hydraulically driven grinding table for grinding knives, scissors, hand and gardening tools and similar workpieces

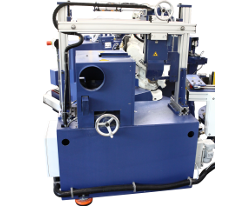

Series HDS >

Rotary table grinding machine for double-sided flat grinding of parallel surfaces

CNC grinding machine with three axes for economic double-sided flat grinding of parallel surfaces of e.g. spanner wrenches, pliers, hammers, chisels, swords or flat grinding of conical surfaces such as adjustable spanner wrenches by single grinding (e.g. nippers) or continuous process (e.g. swords)

Series DRG >

Rotary table grinding machine for grinding flat or conical surfaces

High productivity CNC double rotary table grinding machine with two axes for the grinding flat or conical surfaces on a great variety of parts such as table knives, insides of stamped scissors, wood chisels, spatulas or connecting rods

Series RTS >

Rotary table grinding machine for surface and angle grinding

Rotary table grinding machine with vertically adjustable spindle for efficient surface and angle grinding in continuous production of pocket knife components, hand tools and similar parts

Series PH/PB/NT >

Peripheral grinding machine for serrated and scalloped grinding

CNC controlled peripheral grinding machine with additional vertical axis for scalloped grinding and staggered tooth grinding of knives with up to 600 mm grinding length

Series WS >

Peripheral grinding machine for serrated, scalloped and fluted edge grinding of knives and blades

CNC controlled peripheral grinding machine with up to three axes for scalloped, serrated and fluted edge grinding of knives, mechanical knives, industrial blades and similar workpieces

Series WSM >

Peripheral grinding machine for scalloped and pointed serrated grinding

CNC peripheral grinding machine with up to three axes for plunge grinding of serrated edges on knife blades (e.g. bread or steak knives), scissors and similar workpieces

Series KS >

Peripheral grinding machine for fluted edge grinding of knives

CNC controlled peripheral grinding machine with one axis for fluted egde grinding of knives and blades

Series WSL >

Peripheral grinding machine for scalloped and pointed serrated grinding

The grinding station of the series WSL can be integrated into different machines to produce

scalloped or pointed serrated grinding.

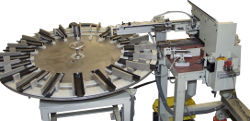

Series RST >

Rotary index table grinding machine for grinding, serrating and polishing of blades

Rotary index table grinding machine available in various configurations for grinding of steak knives, jig saws, scalpel blades or for the grinding of blades with serration

Series HG/NT >

Hollow grinding machine for hollow grinding of knives, hand tools and similar pieces

CNC grinding machine with four axes for the double-sided hollow grinding of kitchen and steak knives, hunting and sports knives, pocket knives as well as hand tools like e.g. jigsaw blades

Series PLM/E/H >

Glazing machine for the machining of knife blades

Hydraulic glazing machine for the machining of knife blades and similar workpieces

Series PLM/NT >

Glazing machine for glazing knife blades

CNC glazing machine with three axes for glazing ground knife blades

Series CG >

Contour grinding machine for machining knife blades, tweezers and scissors

CNC grinding machine with two axes for contour grinding of knives, scissors, hand tools, tweezers, scissors and other workpieces

Series SM >

Sharpening machine for knife blades

Sharpening machine for sharpening knife blades and mounted knives

Series BSM3000/C >

Straight finish grinding and scalloped grinding of knife blades

The BSM3000/C work station is designed for grinding of kitchen knives and similar workpieces.

Series BSM1500/TTGB >

Straight finish grinding and "gothic arch" grinding of steel strips

Key application for the steel strip grinding station BSM1500/TTGB is grinding of razor blade edges with a convex profile (gothic arch).

Series BGM1500/E/D >

Straight finish grinding, scalloped and serrated grinding of steel strips

The grinding machines of the series BGM1500/E/D are designed for one- or double-sided grinding of doctor blades, knives for the food industry and similar workpieces.

Series DEB1500 >

Grinding and polishing double-edged razor blades

The solid steel strip grinding and polishing station of the series DEB1500 is configured for the machining of the classic double-sided razor blade with three angles.

Breakers >

Breaking units for blades for steel strip grinding machines

The breakers can be integrated into steel strip grinding and polishing lines or be mounted as a separate breaking unit with decoiler.

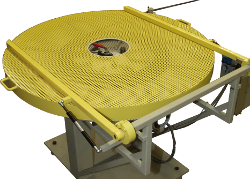

Spooling systems >

Decoiling systems for steel strip grinding and polishing lines

Augst Nell jr. and Werner Peters offer the following spooling systems which can be integrated into a strip grinding and polishing line.

Series DWP/2S >

Polishing of forks and cutlery knives

The double shaft polishing machine type DWP/2S polishes both sides of forks, cutlery knives and similarly shaped workpieces.

Series DWP/2M >

Polishing knife handles

The double shaft polishing machine type DWP/2M is designed for polishing of knife handles at monobloc knives, mounted knives and hollow handles.

Series PS >

CNC controlled polishing of knife handles, bone plates and similar workpieces

The CNC controlled double shaft polishing machine of the series PS is equipped with a control system which enables a programming and storing of all process parameters.

Series PC >

CNC controlled polishing of knife blades

The CNC controlled double shaft polishing machine of the series PC is designed for rough and final polishing of knife blades up to a length of 650 mm.

Series FPV >

Polishing the cutting edges of circular knives

The FPV series polishing machine is designed for sharpening and polishing the cutting edges of circular knives.

Series RSP/1B/2P >

Sharpening of knife blades

Robotic cell with one belt grinding station and two polishing stations for sharpening and polishing of knife blades

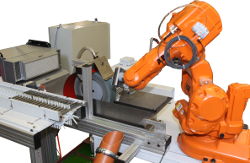

Series RSP/2B (1) >

Contour grinding of knife blades

Robotic cell with two belt grinding stations for contour grinding of knife blades and similar workpieces

Series RSP/1B >

Serrating of knife blades

Robotic system for serrating knife blades with a a toothed chopper disk

Series RSP/2B/1M (3) >

Flat grinding of handles

Robotic cell with two belt grinding stations and a magazine system for flat grinding of handles

Series RSP/3P >

Polishing of handles

Robotic cell with three polishing stations for polishing of knife handles and similar workpieces

Series RSP/6B/1M >

Grinding of knife handles

Robotic cell with six belt grinding stations for grinding knife handles and similar workpieces

Series RSP/5B/1F/2L >

Milling and flat grinding of handles

Robotic cell with five belt grinding stations and one milling station for milling and flat grinding of knife handles and similar workpieces