Cutlery

Solutions

The Berger Gruppe produces machines for processing cutlery parts.

| Polishing machines are designed for rough and final polishing of spoons, forks and table knives – from bowl to handle. | Rotary index table grinding machines machine the edges and tines of cutlery parts. |

For utility cutlery see knives.

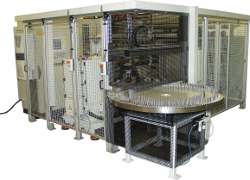

Series KBR >

Rotary index table grinding machine for machining cutlery edges

The rotary index table grinding machine KBR6 realizes a complete edge machining all-around the workpiece with a machine which consists of two one-sided and two double-sided belt grinding stations.

Series ZS >

Rotary index table grinding machine for tines

The rotary index table grinding machine of the series ZS machines forks with two, three or four tines. By the use of a folded grinding belt the run-out radius is ground cleanly.

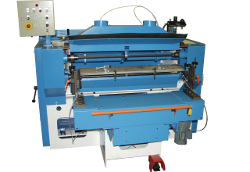

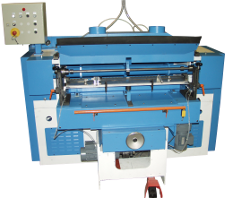

Series DWP >

Rough and final polishing of cutlery items

For rough and final polishing of spoons and forks different models of the series DWP are assembled to one production line.

Series DWP/2K >

Polishing the outer edge of cutlery parts

The polishing machine type DWP/2K polishes the edges of cutlery bowls and handles in two steps.

Series DS >

Polishing of the handle neck

The double shaft polishing machine of the series DS is used for rough and final polishing of the narrow edge area of the handle neck (transition between handle and bowl) of spoons, forks and similar workpieces.

Series PS >

CNC controlled polishing of knife handles, bone plates and similar workpieces

The CNC controlled double shaft polishing machine of the series PS is equipped with a control system which enables a programming and storing of all process parameters.

Series EB >

Polishing of the outer edge of cutlery part ends

The single shaft polishing machine of the series EB is an end facing machine. Depending on its configuration, it can be used for rough or final polishing of spoons, forks or similar items.

Series EWP >

Polishing of deep cutlery bowls

The automatic single shaft polishing machine of the series EWP machines the inner and outer side of cutlery bowls.