Robotic process technology / automation

integrating | handling | sorting | measuring

Different production processes can be integrated into one line and handled automatically. Workpieces can be fed in a disordered manner via conveyor belts, separated, detected, gripped by the robot and fed to subsequent processes.

bus-based detection of sensor signals | integration | measuring technique / programming | process automation / handling technology | sorters

System integration >

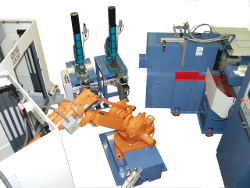

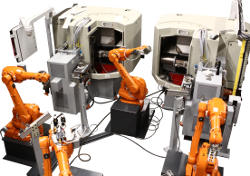

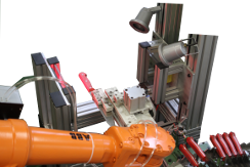

Integration of different production processes into robotic cells

Different production processes such as bending presses, painting plants or packing machines can be combined and integrated into one robotic cell.

Series SE >

Sorters for robotic cells

Sorters store workpieces made for cut material or insert them into a magazine.

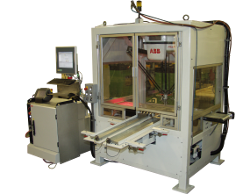

Robotics >

Robotic handling for loading and unloading

Depending on the requirements, there are a variety of options, e.g. loading a single machine, several machines or integrating a grinding machine into a production cell.

CNC technology >

CNC handling system for loading and unloadingThe Berger Gruppe offers CNC handling systems with full CNC-control of vertical and horizontal motions of load and transfer.

Pneumatic systems >

Pneumatic handling system for loading, transfering and unloadingThe Berger Gruppe offers various solutions for pneumatic handling technology, such as in connection with conventional and CNC-controlled machines using pneumatic cylinders.

Camera measuring systems >

Camera measurement of workpieces

Development of standard measuring systems for various applications for the measurement and compensation of automated measurements / contours

Laser measuring systems >

Laser measuring for workpiecesDevelopment of laser measuring systems for the measurement and compensation of automated measurements / contours.

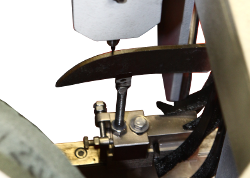

Mechanical measuring sensors >

Mechanical measurement of workpieces

The mechanical probe is used to record the contour on grinding machines of the CG2 and HG2/NT2 series.

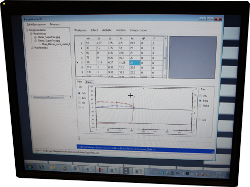

Programming >

Menu-driven interfaces for complex system controls

The programming is used for robot grinding and polishing cells of the RSP series.