Pressing and stamping industry

Solutions

At pressing and stamping lines the burr damages the tools and the rolls. To eliminate the burr, mostly a deburring device of the series UNO is integrated into a pressing line.

For many production processes, the strip must be flat and straight. The levelling machines of the Berger Gruppe straighten coil set and eliminate saber formation.

Series UNO >

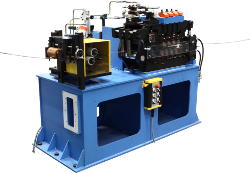

Strip edge trimming machine with 2 tools

Strip edge trimming machine working with one tool each side. It’s designed for the deburring of the strip edge or for simple contours at the strip edge.

Levelling machines >

Flat levelling, vertical levelling and calibrating of strips

Machines for flat and vertical levelling and calibrating of strips. The machines are integrated into strip processing lines.