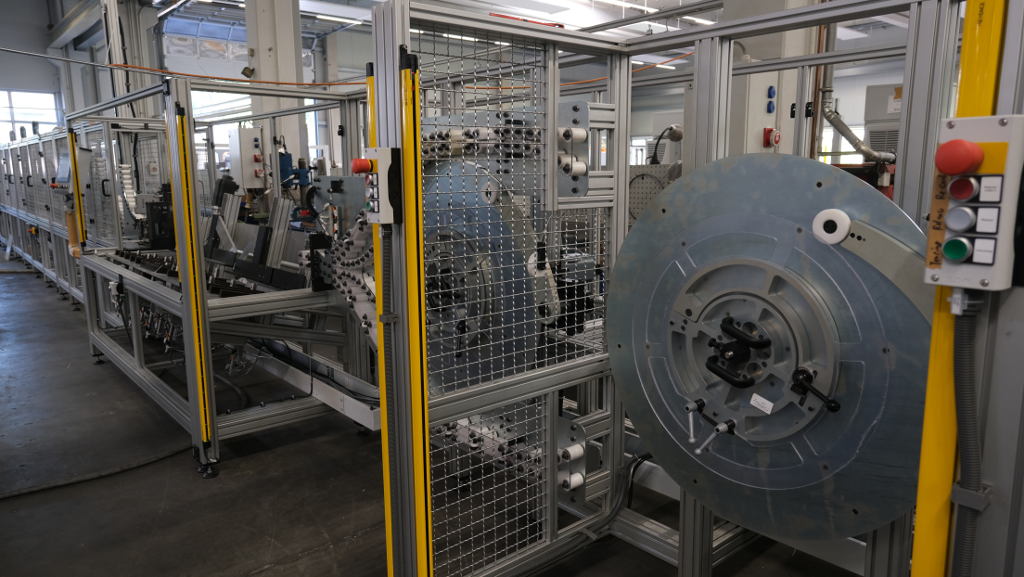

QUATTRO300/S | The JULIUS strip edging machines of the new generation are designed for high stress processing. ...

Archives

Our overview

2021

Milestones of the Berger Gruppe in 2020

In 2020, the Berger Gruppe has developed the following new technologies:

Test bench for saws

RSP/3W/1R | The presented test rig controls the quality of saw blades. It also determines the ideal cutting parameters (force/feed, cutting angle ...)…

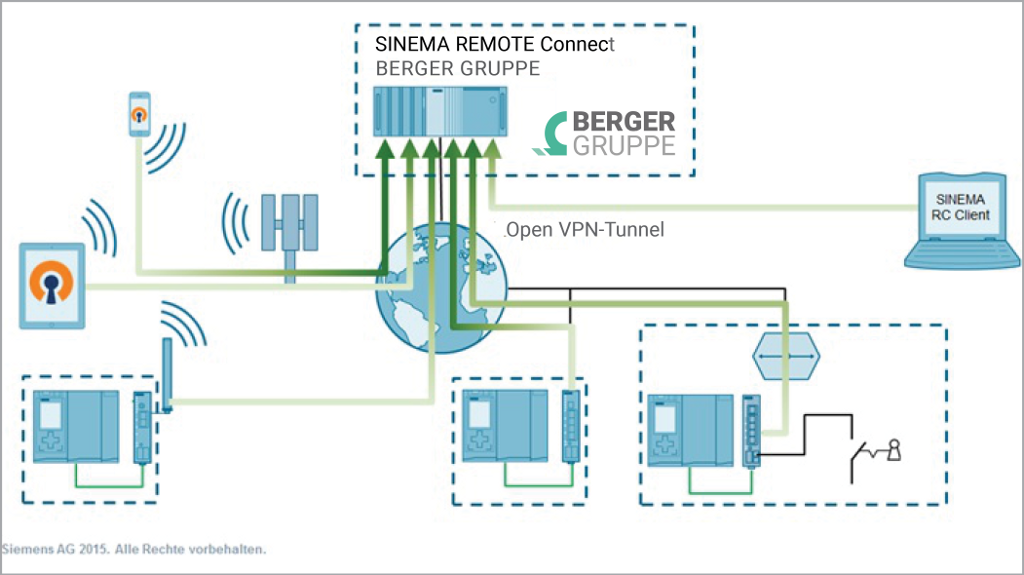

Remote maintenance with data security

Sinema Remote Connect | The remote desktop solutions provide data security for connections. The connection is made from the customer's router to the…

Robot bin picking system

RAA | Handling of non-sorted workpieces: A camera system with high-resolution cameras – in this case from Keyence – detects the position of the…

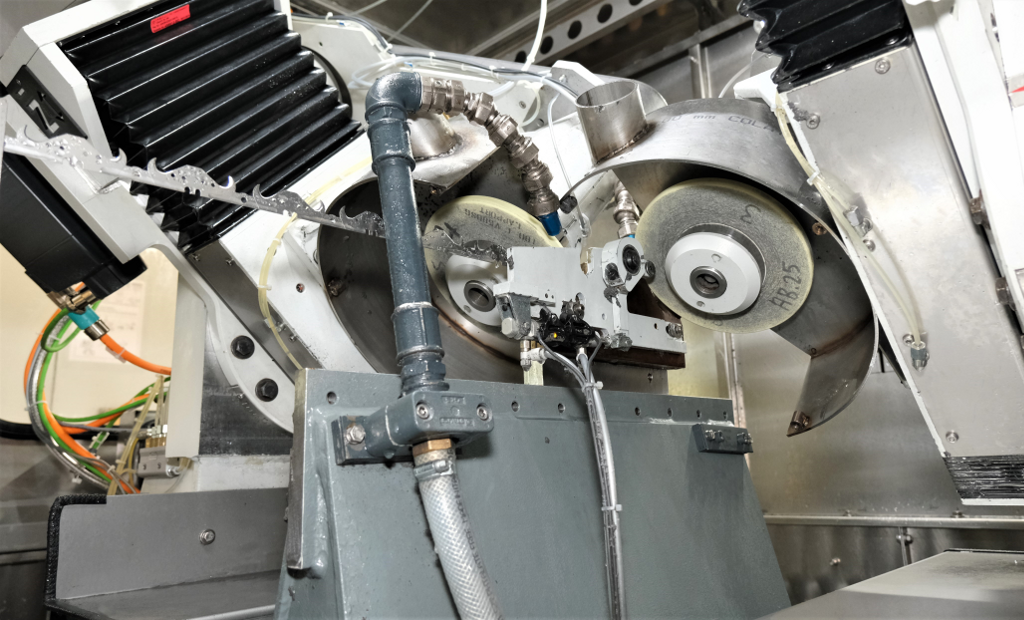

Grinding of hooked blades

BSM/HK | The strip grinding machine of the HK series is designed for grinding and polishing hooked blades.

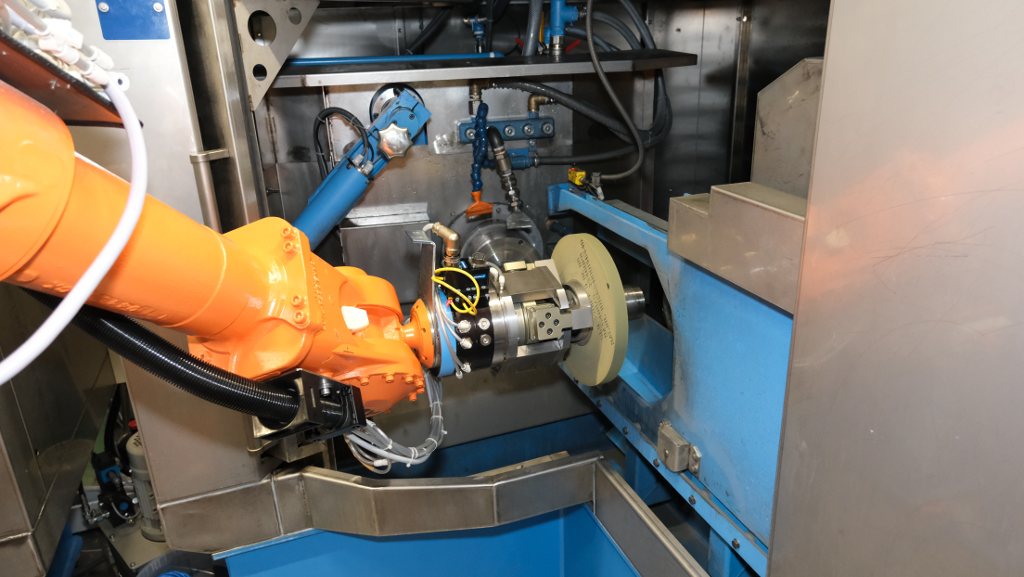

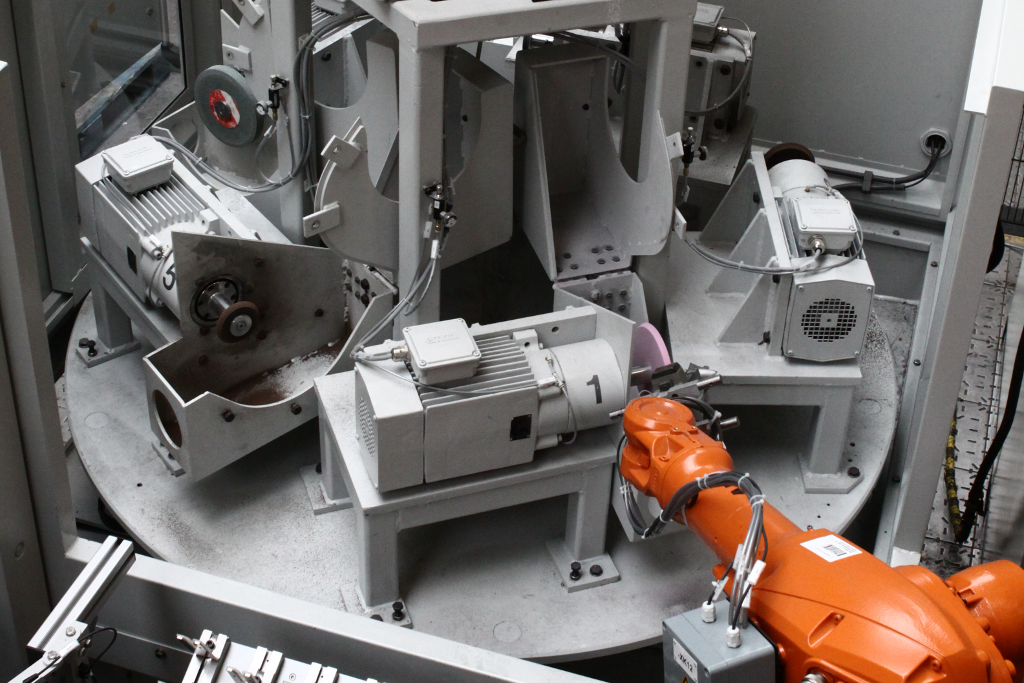

Robot grinding wheel changing system

RFS2/NT | A robotic grinding wheel and gripper changing system is integrated into a circular knife processing cell. The cell consists of two…

Levelling the edge bow of steel strips

FLS099 | The longitudinal levelling machine is designed for levelling the edge bow of steel strips.

Measuring, warning, saving

The Heinz Berger Maschinenfabrik in Kohlfurth wants to be better prepared in the future when there is a risk of flooding. WSW will help to set up an…

2020

Milestones of the Berger Gruppe 2019

En 2019 el Berger Gruppe ha desarrollado nuevas tecnologías como las siguientes:

Internship special mechanical engineering - robotics

Internship robotics | Accompanying the lecture in the field of special mechanical engineering of the University in Wuppertal (Germany), an internship…

Robotic machining with CNC rotary table

RSP/RT | The robot cell is equipped with five processing stations mounted on a rotary table. The workpieces is guided by robot.

Strip edge trimming for heavy duty use

BHR/BKB/S | The strip edging line of the BHR/BKB/S series is employed when the strips are processed with high material removal.

Angular Blade Inspection System

ABISY | Inline Inspection System for quality assurance in the grinding process of steel strip and in robot cells after the grinding process

Virtual in-house exhibitions at Berger Gruppe

VR | The Berger Gruppe would like to invite you to take a virtual tour of the production with them.

Handling Award 2020

Berger Feeder | Camera-supported feeding of workpieces in processing cells

Robotic sharpening of circular knives

RSP/2S | Robotic cell for sharpening and re-sharpening of circular blades and similar workpieces

Experience, discover, develop – the industrial robot

BeST course for students | In cooperation with the Bergisches Schul-Technikum on October 13 and 14, the Berger Gruppe offered students the opportunity…

Robot surface processing

RSP | Robot-controlled surface processing of geometrically complex castings with 3D contour detection and intelligent force-torque sensor technology

Grinding of brake and clutch discs

RTF | CNC machine designed for grinding brake and clutch discs and similarly shaped workpieces

2019

Milestones of the Berger Gruppe 2018

In 2018 the Berger Gruppe has developed new technology as follows: RSP Robotic grinding system with automatic gripper exchange system, 3D duplex…

Radii and hollow grinding on garden shears

BG2/RH/HS/NT | The CNC flat bevel grinding machine of the series BG2/RH/HS/NT is the core piece of the presented machining cell. By employing an…

Flat and radii grinding of big workpieces in one clamping

BG3/RH/VSS/V/NT | The CNC-controlled flat bevel grinding machine BG3/RH/VSS/NT presented here is designed for machining curved cutting edges on large…

Steel strip grinding line for microtome blades

BSM | The steel strip grinding plant presented here is designed for the processing of steel strip for the production of microtome blades with three…

Feeding and separating bulk material

Berger Feeder | In processing cells for bulk material, the workpieces – in this case pocket knife parts – are fed via the Berger Feeder Transport…

Rough and final polishing of professional knives

DWP/PS1000 | The machining cell presented here is designed for rough and final polishing of professional knives.

Dancing robots at the facilities of the Berger Gruppe

GCU festivity | During the GCU festivities, six students and trainees were awarded the GCU sponsorship prize.

Creep feed grinding of crush cut rotary blades

WSM1/SP | CNC creep feed grinding machine for score/crush cut rotary knives

The peripheral grinding machine is designed for radii grinding on the…

2018

Milestones of the Berger Gruppe 2017

In 2017 the Berger Gruppe has developed new technology as follows: RSP Robot controlled exchange system for grinding belts, DRG Single point dressing…

Deburring and milling of die-cast aluminium parts

RSP/1R | The robotic station RSP/1R is designed for deburring and milling die-cast aluminum parts.

Up to five rotating tools – such as grinding…

Tube production: Increase of welding speed by 50% due to strip edging

QUATTRO/600 | The strip edging machine of the series QUATTRO600 trims the strip edges by metal-cutting working. It is equipped with up to twelve tools…

Duplex camera measuring system for circular knives

VR1-CNC/FPV | With two cameras the Duplex camera measuring system measures the diameter and the resting thickness of circular knives. With a precision…

CNC hollow grinding machine with robot controlled sharpening of knives

HG2/NT2-CNC / SM3-CNC | The robotic cell is equipped with a hollow grinding machine of the series HG2/NT2-CNC and a sharpening machine of the series…

Berger Machine Interface 4.0

BMI4.0 | The Berger Machine Interface 4.0 integrates a universal bus-based detection of sensor signals such as temperature of cooling lubricant engine…

CNC strip grinding machine with hydrostatic spindles for low-vibration processing

BSM-CNC | The steel strip grinding line is designed for two-sided straight micro-grinding of steel strip for the production of cutting lines ...

EffProSchliffUp – Recycling of abrasive slurry

EffProSchliffUp | Since 1st of November 2018, the project "Resource efficient production of shape-ground metallic products with subsequent up-cycling…

2017

Milestones of the Berger Gruppe 2016

In 2016 the Berger Gruppe has developed new technology as follows: BG0/ZAA CNC grinding machine for wood drills with taktile measuring system, RSP/RSM…

2. TIN Service Manager Meeting

Optimized service for customers of the tube industry | On February 23rd the service manager of the Tube Innovation Network met for the second time.

Symposium mechanical knives in Wuppertal

Symposium | On March 2nd the professional association tool industry (FWI) organized a symposium about the production of mechanical knives.

Robotic cell for the machining of lids

RSP/1B/1P | The robot grinding and polishing station is designed for the machining of lids and similar workpieces.

CNC controlled kinematic guide arm

BHR80 | The newest strip edging and traverse winding line is equipped with a computer controlled kinematic guide arm.

60 years Heinz Berger Maschinenfabrik

Grinding and polishing technology since 1957 | This year Heinz Berger Maschinenfabrik GmbH & Co. KG is celebrating its 60th anniversary. The…

Extension of the service department

The service department has moved to a new location.

The Berger Gruppe has extended its service department both in terms of space and human resources.

Tube Innovation Days stop off in Mexico

After successful events in Asia, Europe and North America, the Tube Innovation Days made a stop in Mexico this year on the 3rd and 5th of October.

Cutlery symposium

Symposium of the cutlery association (IVSH) in the premises of the Berger Gruppe

2016

Milestones of the Berger Gruppe in 2015

In 2015 the Berger Gruppe has developed new technology as follows: RAA Robot welding system for rotary saws with camera control, RVZ/...

Flat grinding of long knives

FS-CNC | The CNC controlled flat grinding machine grinds long knives with a maximum length of 4000 mm.

Strip edging with strip centering control

DUO2000 | Due to a strip centering control which is integrated into the strip edging machine it is possible to chamfer strips with a maximum width of…

Serrated grinding of mechanical knives

PH/PB3-CNC | The peripheral grinding machines PH/PB3-CNC is designed for serrated grinding of mechanical knives. The machines includes a robotic…

Simultaneous serrated grinding

SVZ-CNC | The serrated grinding machine SVZ-CNC achieves a serrated edge grinding on up to 44 strips simultaneously.

Extension of the production facility in Wuppertal (Germany)

For the third time in eight years the Berger Gruppe has extended its production facility in Wuppertal (Germany) by building a new production hall.

Surface quality measurement with confocal with 3D microscope

For even better cutting quality of your knives the Berger Gruppe employs a confocal 3D microscope which transforms nearly all surfaces into precise…

Robot plant for the machining of knives

RSP/2B/1P/2M and BG1/NT2-CNC | The robot plant combines several processing steps transforming a raw blade into a finished blade.

2015

Economic Award of Wuppertal 2015 for the Berger Gruppe

This year the economic award of Wuppertal in the category "company of the year" was given to the Berger Gruppe.

CNC grinding machine for surgical gouge blades

WS6-CNC | The two-axle grinding machine WS6-CNC is designed for grinding of surgical gouge blades with a maximum length of 100 mm. The grinding motion…

Peripheral grinding machine for serrated grinding of circular knives

RVZ-WSL-CNC | The CNC controlled serrated grinding station machines circular knives with a diameter of 50–500 mm. The machine is equipped with a…

Double shaft polishing machine with extended stroke

DWP/2S | The longitudinal stroke of this double shaft polishing machine is extended from 320 mm to 500 mm so that even knife blades with a maximum…

Blade breaker with loop control and storing table

BR5 │ The breaker of the series BR5 is designed for breaking blades and storing them in a magazine system. The breaker can achieve 500 breaking cycles…

Multicoil for short assembling times

Multicoil │Thanks to a multicoil system multiple coils can be taken simultaneously and handled one by one.

Milestones of the Berger Gruppe in 2014

In 2014 the Berger Gruppe has developed new technology as follows: BDG CNC grinding machine for strip steel with resin bonded diamond cup wheels, WSM/…

2014

Measuring system for robotic sharpening station with laser distance control

RSP1S1P │ A measuring system with laser distance control is integrated into a robotic sharpening station of the series RSP1S1P.

CNC belt grinding machines BSS14/PH and BSS14/RV

BSS14/PH CNC belt grinding machine for the finishing of the outer face of knife handles. The workpiece is held and moved vertically by a CNC feeder.…

Thickness calibration – strip optimization for further production processes

FW50 │ Two window rollers of the series FW50 are combined in succession to calibrate the strip thickness with an accuracy of ± 0,005 mm.

CNC grinding machine BSM3000/300-CNC/E for spring steel up to a width of 150 mm

BSM3000/300-CNC/E │ The presented CNC controlled strip grinding machine is designed for the machining of spring steel with a maximum strip width of…

Robot controlled installation system for high pressure polish pistol

RP6/RP5 │ The robot controlled installation system adjusts automatically the angle and the distance of high pressure polish pistols in robot polishing…

Milestones of the Berger Gruppe in 2013

In 2013 the Berger Gruppe has developed new technology as follows:

| BSS14/PH | CNC belt grinding machine for the outside finishing of knife handles |

| B… |

News archives

Here you find a list of all the news of the last years.